Let's Talk

Interested in learning more about what Barracuda has to offer? Please contact us at 985-262-4776 or complete the form below to send us an email.

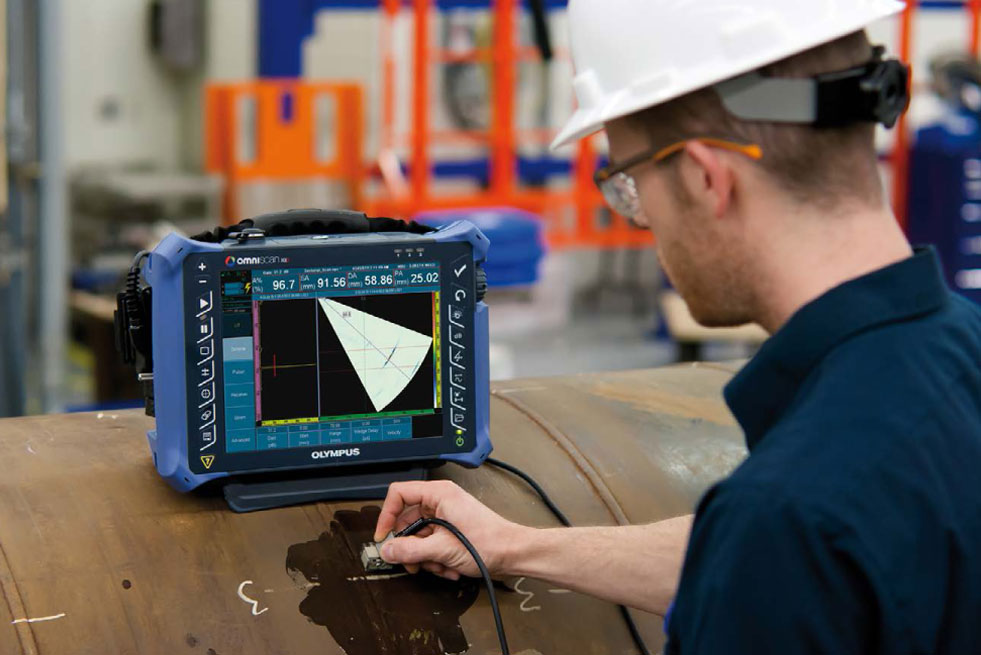

VISUAL

A visual inspection or visual examination of objects, parts or components is the oldest and reliable non-destructive testing method

Quality Assurance

The test method is applied to almost every product as a quality assurance tool. The most detrimental unacceptable discontinuities in the objects or items are the surface opening discontinuities.

Visual scanning, inspection or testing can successfully detect these unacceptable surface discontinuities without applying expensive test methods.

Visual testing is performed either by a direct technique or by a remote (that is indirect) technique. The remote technique may include accessories such as mirrors, borescopes, video probes or cameras to correct for the distance or angles of view.

Visual test equipment is designed to detect structural characteristics of a part. These characteristics range from simple surface discontinuities on flat surfaces to various fabrication of inservice discontinuities in complex geometries.

Visual Inspection Techniques

Barracuda Specialty Service LLC provides a variety of VT visual inspection techniques to multiple industries.

Barracuda Specialty Service LLC provides a variety of VT visual inspection techniques to multiple industries. We also employ a number of certified individuals to perform this inspection.

Our employees hold multiple certifications in various societies such as:

Barracuda Specialty Service LLC can provide this expertise with our diverse group of inspectors.![]()

Contact the VT Visual Inspection experts to discuss your visual inspection needs.